Case Study

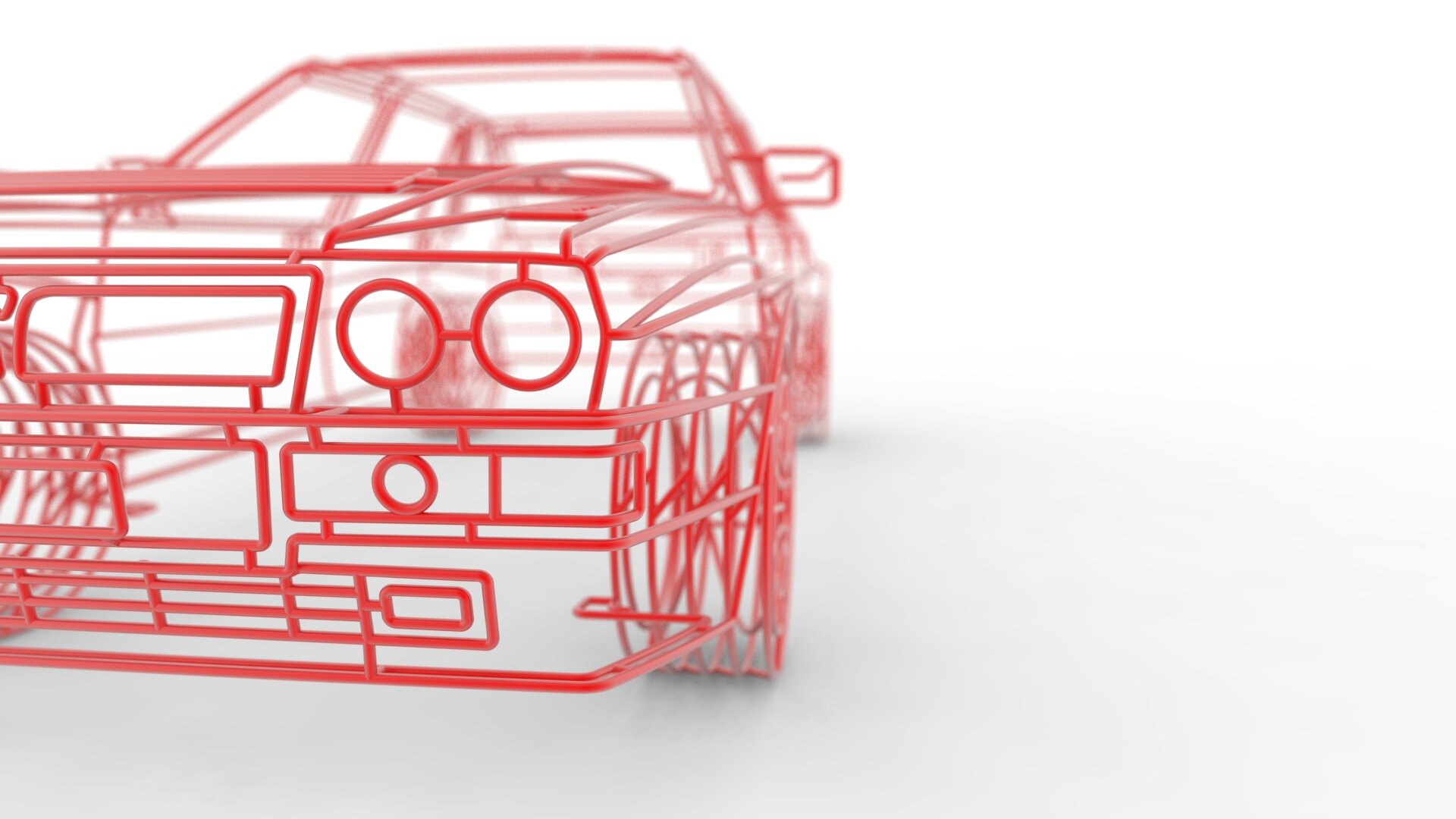

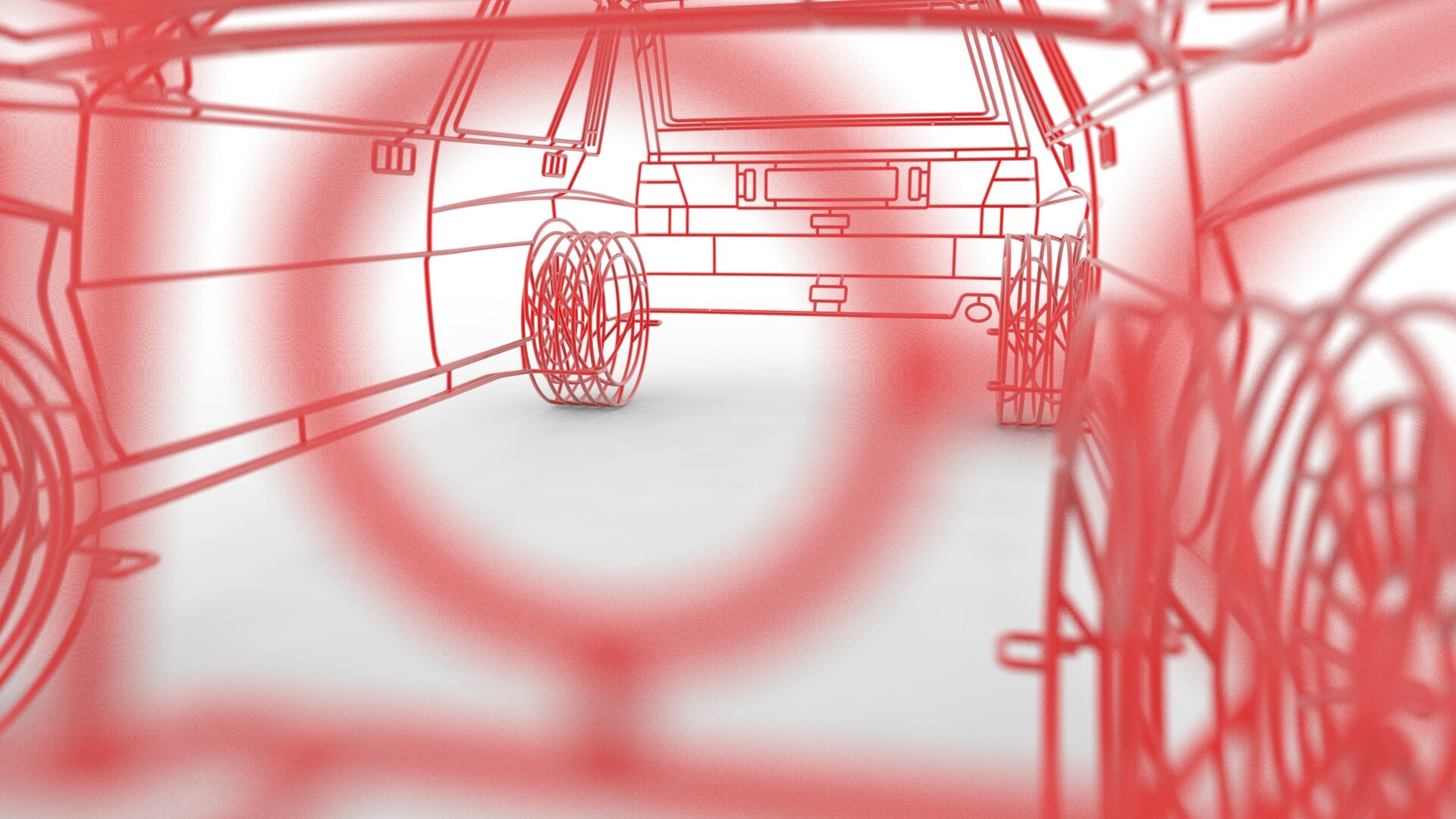

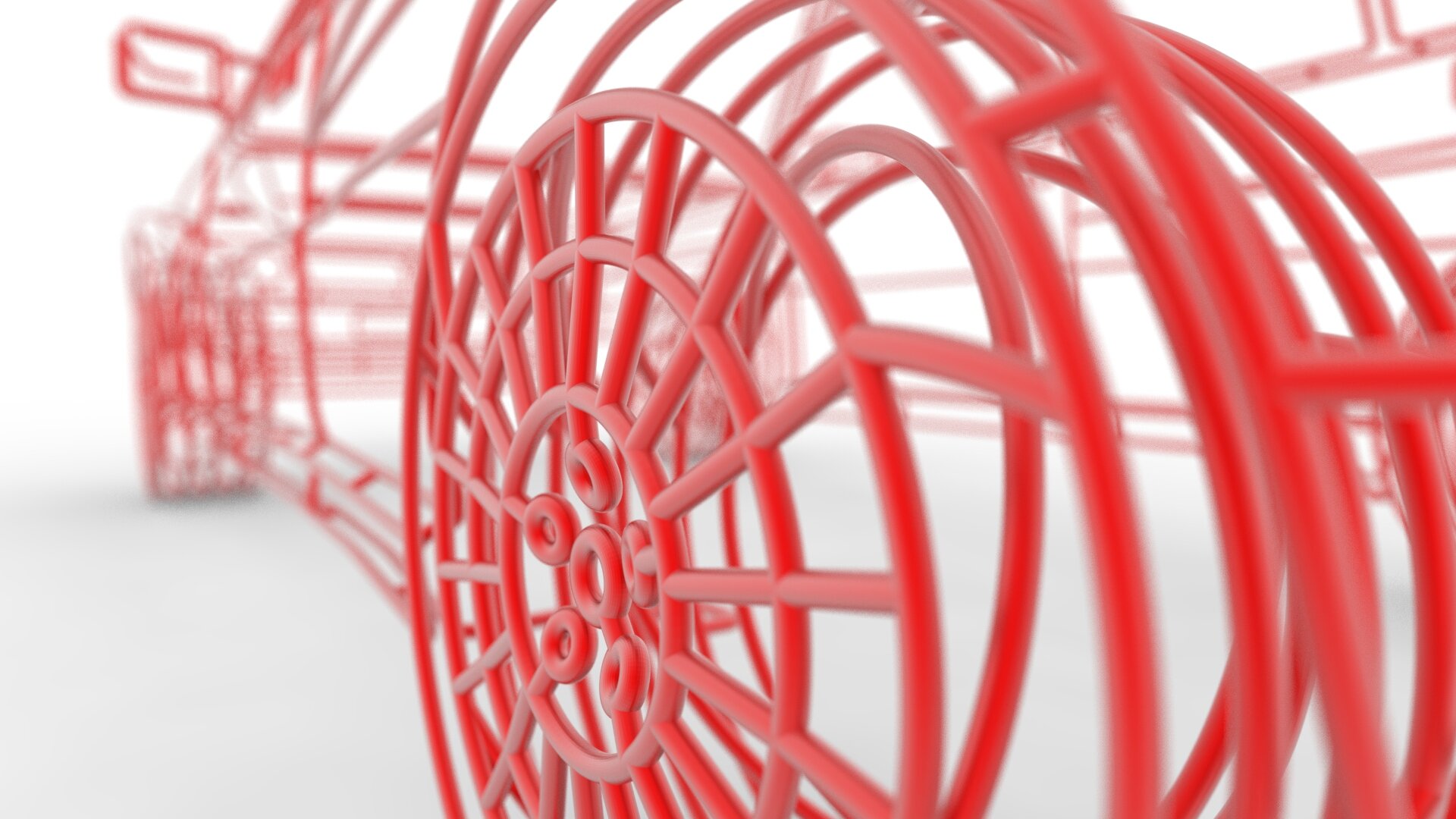

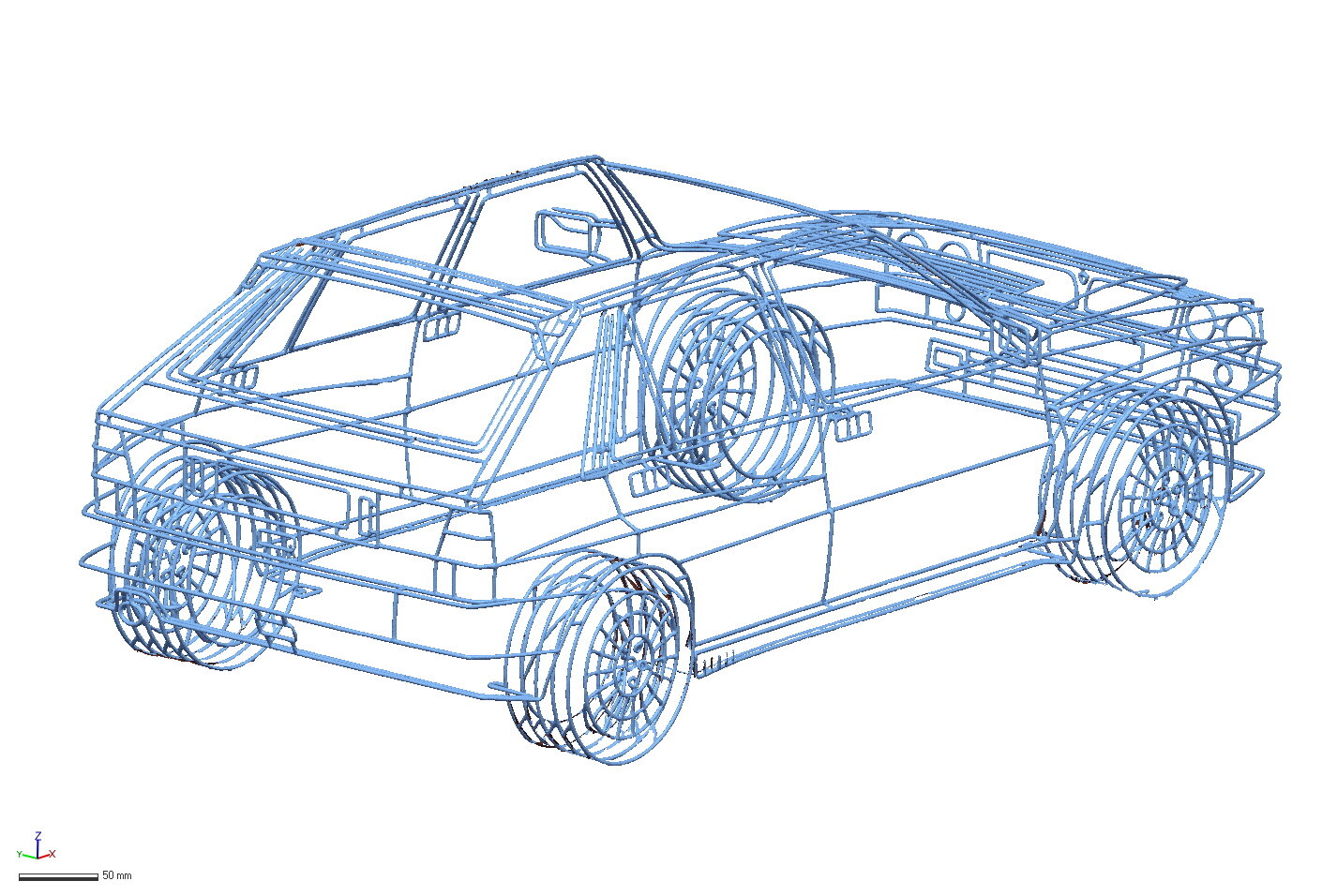

Lancia Delta Wireframe

Working with the extremely talented artist Benedict Radcliffe, we were asked to scan and reverse engineer his sculpture of a 1:5 scaled wireframed Lancia Delta. This reverse engineered model could then be scaled further and 3D printed for online sales.

Benedict Radcliffe.

Benedict Radcliffe (born 1976) works across a wide spectrum of disciplines, creating everything from cars and bicycles to furniture and household objects, as well undertaking various architectural commissions and signature sculptural pieces for clients across the globe.

After graduating from the Mackintosh School of Architecture in Glasgow, Radcliffe staged his first exhibition in the city, featuring his 'Modern Japanese Classic'- a full size 3D wireframe Subaru Impreza, subsequently purchased by collector, David Roberts. As a result of the show, he received commissions from Comme des Garcons, Puma and Paul Smith.

Radcliffe left Glasgow in 2007 and set up a studio in London. His clients include a broad range of the best known and most prestigious brands in the world - from manufacturing and technology to transportation, fashion and the luxury goods sector.

In the 2011 'The Power of Making' show at The Victoria and Albert Museum his work featured alongside Thomas Heatherwick and Ron Arad.

Radcliffe was heavily involved in 2012 with Honda's Dream Factory and named as one of its twelve 'Cultural Engineers'.

He has been invited to exhibit and talk around the world and his work is held in private collections in Europe, America and Japan.

Scanning.

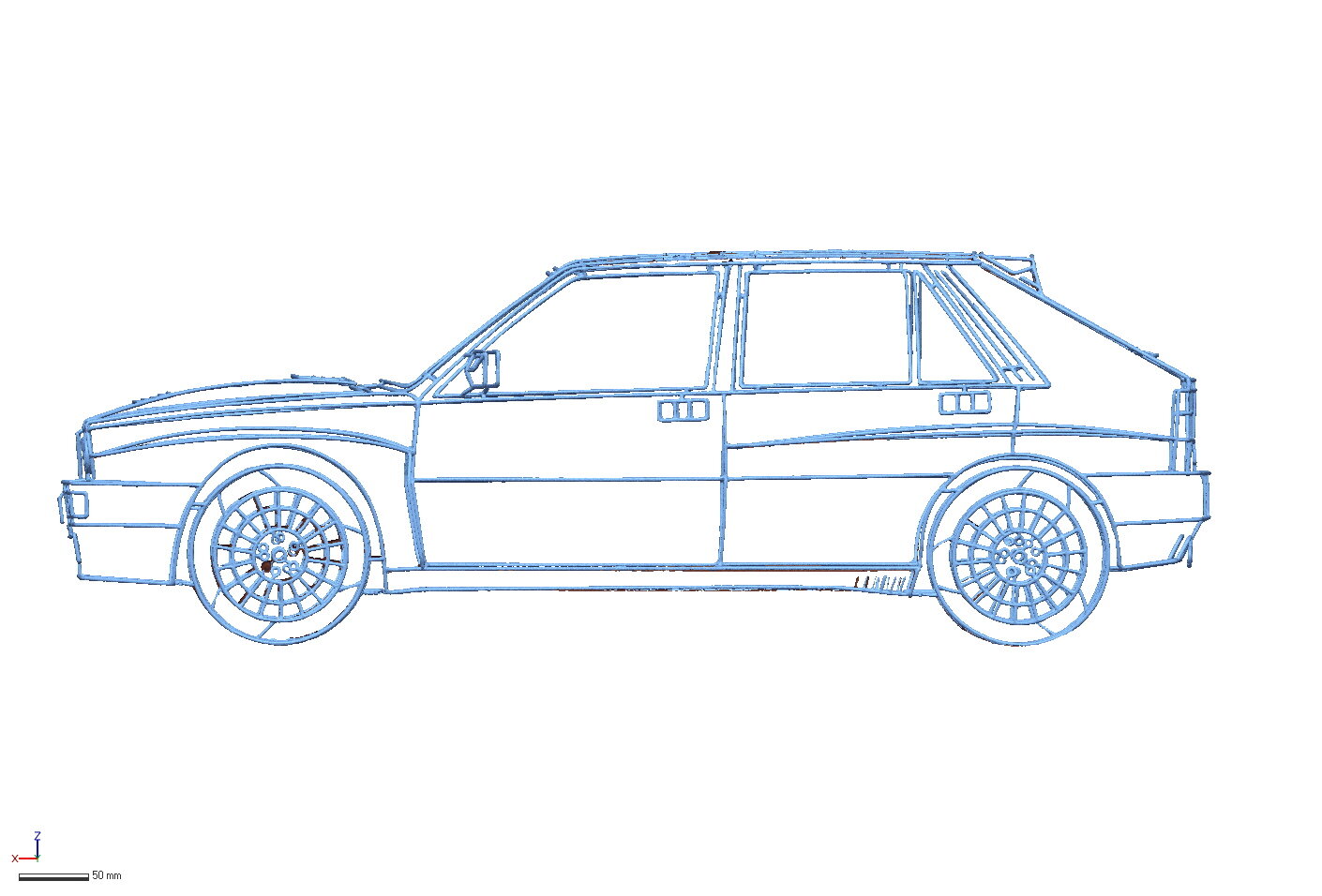

Benedict had already hand sculpted a 1:5 wireframed replica of the Lancia delta. The idea was to 3D laser scan, reverse engineer and 3D print smaller replicas for online sales.

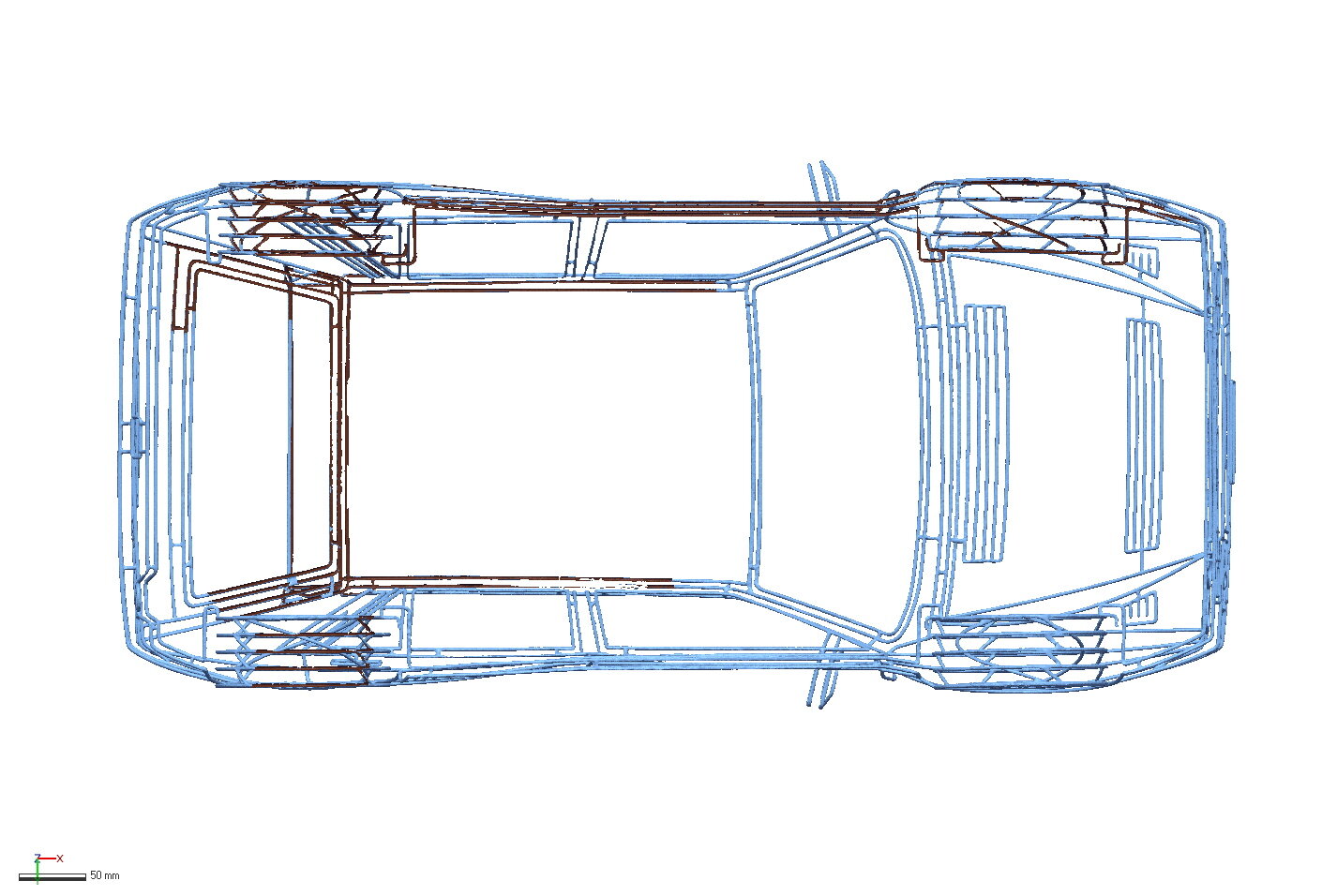

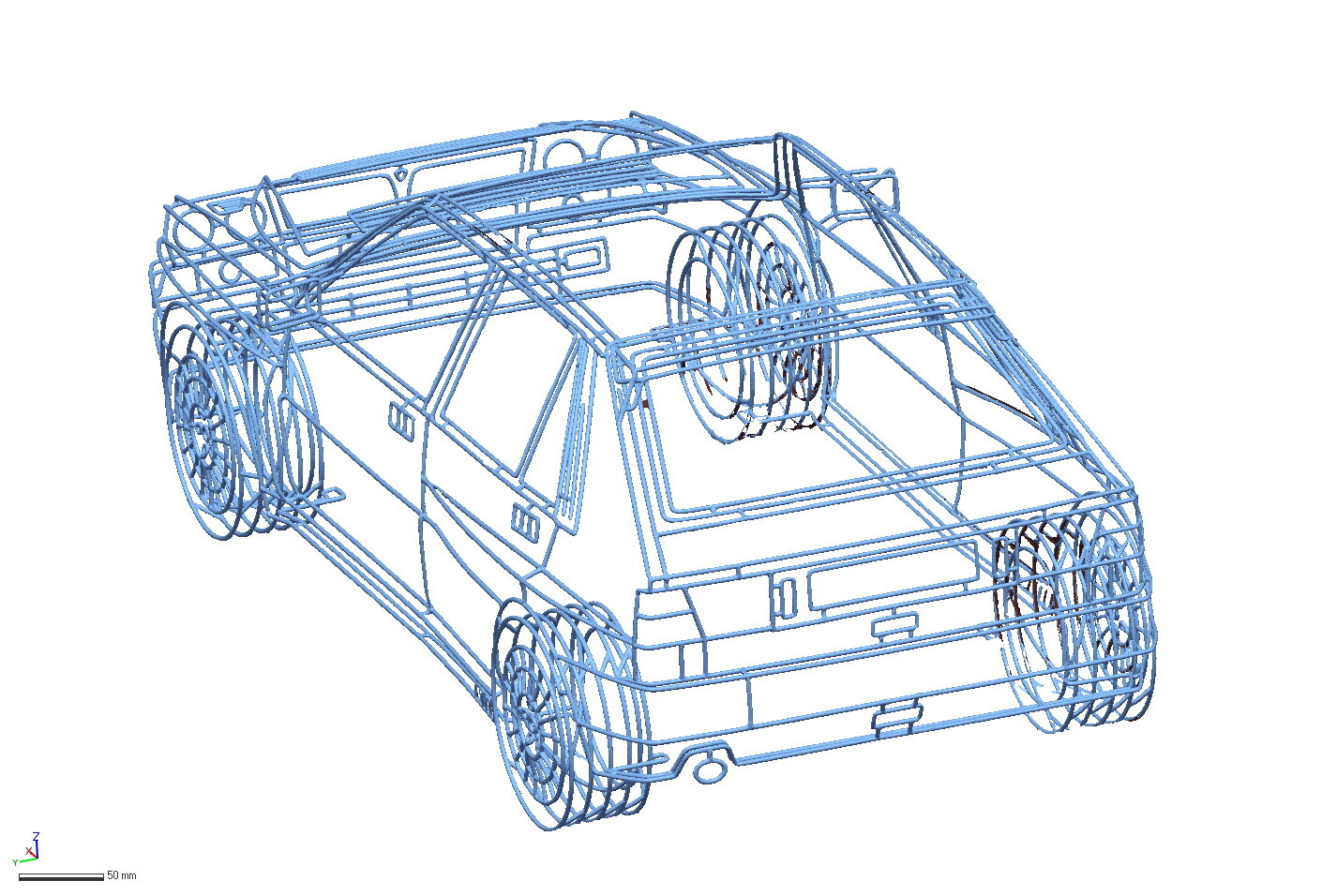

Reverse Engineering.

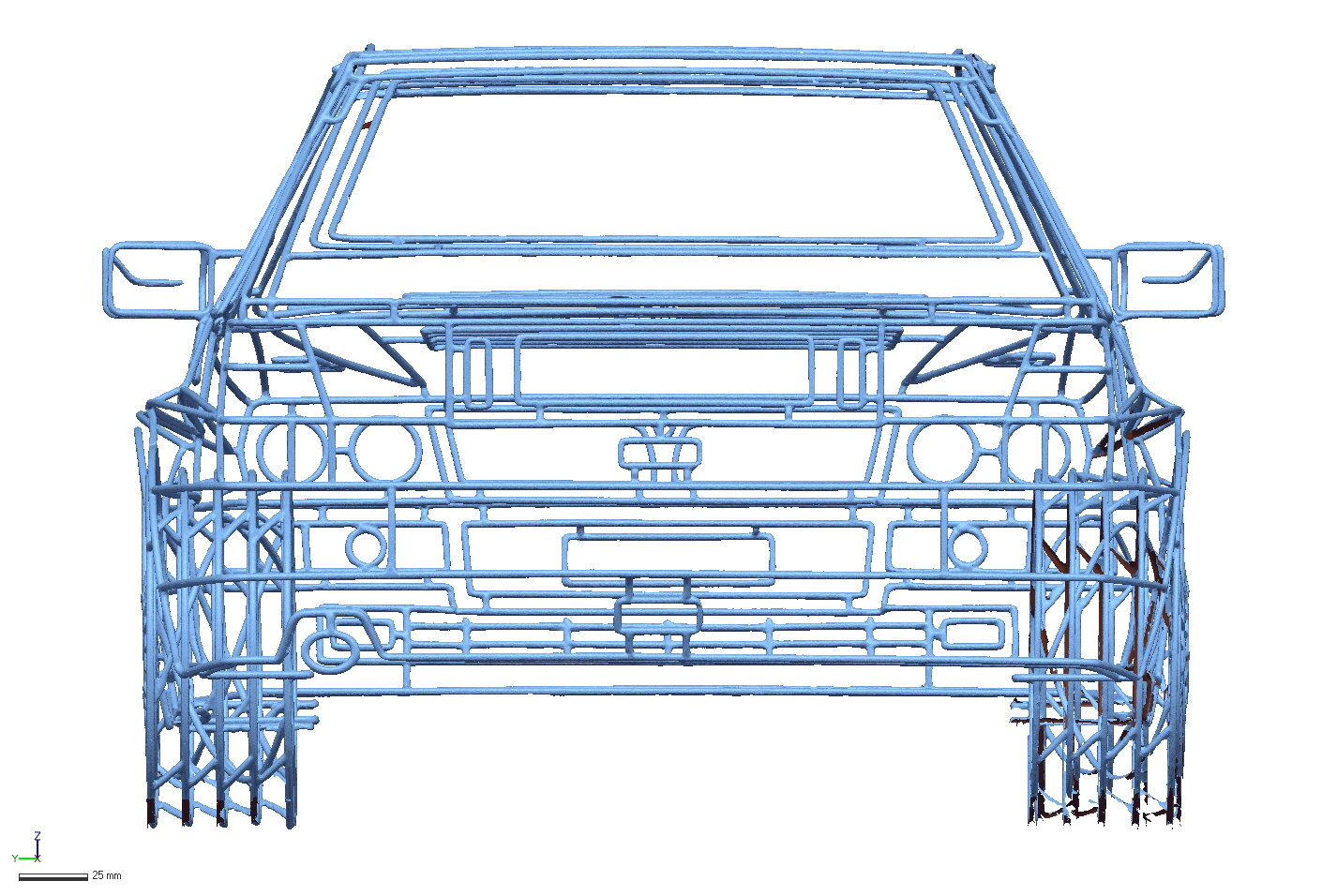

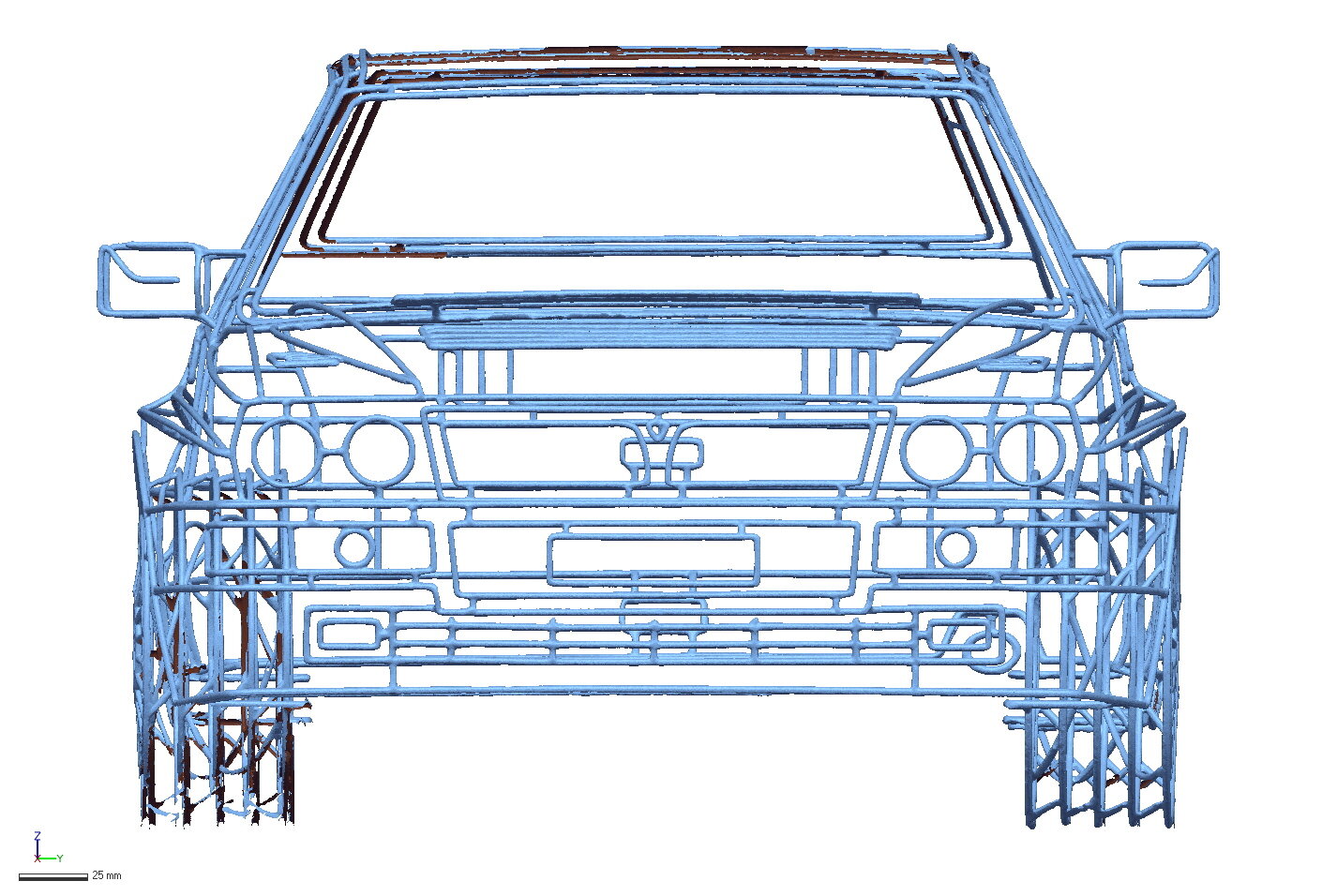

Using Geomagic Design X, we could import our raw scan data and use this as 3D reference for creating the curves, bends and profiles.

The most challenging aspect of this project was the sheer volume of bends and profiles required to complete the model. To give this some perspective our final model consisted of 498 planes, 579 sketches, and 258 reference points.

Anyone with a certain level of CAD experience will be aware of 3D sketches/splines. However, we chose to stay away from 3D sketches for this model because if this were to be remanufactured using a pipe bending cnc, it would be much more challenging to reproduce these curves.

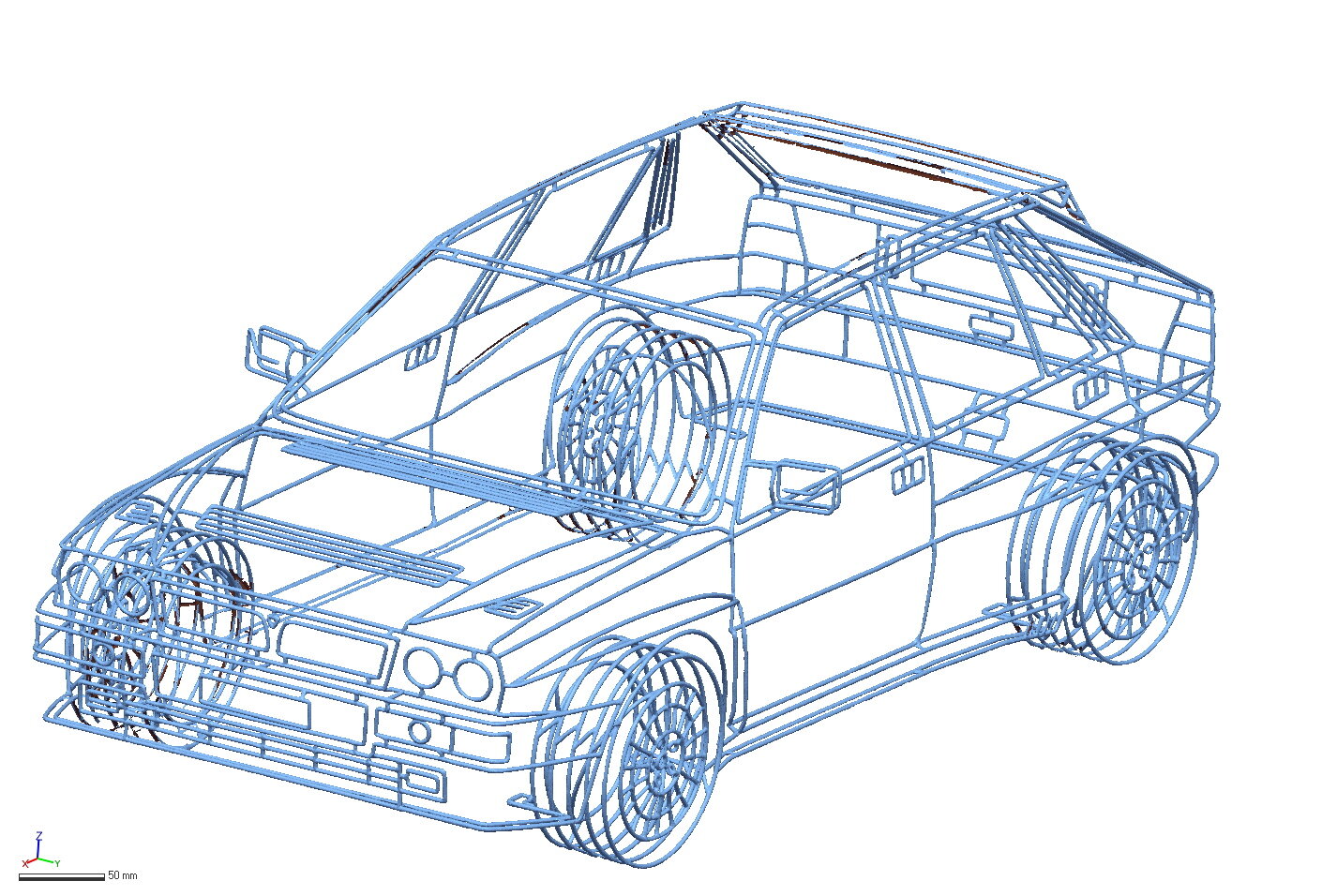

Final Model.

Here is our final model rendered up in KeyShot.