Case Study

Windup Doorbells

Scan, model, render and AR for consistent web assets and marketing.

H120 handheld Laser Scan.

The majority of the doorbells that needed scanning had metallic reflective surfaces. Traditionally reflective surfaces such as these are hard to scan with lasers as they can bounce off the surface and capture inaccurate data. However, this made easy work for our Nikon H120 scanner which, thanks to its blue light technology, can handle pretty any material we throw at it.

Key Benefits of the H120 Scanner.

Extremely low noise data thanks to Nikon lens and blue laser technology

Scanner accuracy of 7 microns

Able to measure the most precise details on parts of any size

Measures at over 450 stripes every second on all materials

Full Field-of-View indicator for precise scanning

Real-time optimization of the laser for every single measured point

Designed for use under all shop floor or field conditions

Parametric Model.

Where possible, we parametrically model each product using Geomagic Design X. Our Design X software allows us to accurately reference the parts scan (STL) data in the background to ensure the final model is accurate and within tolerance.

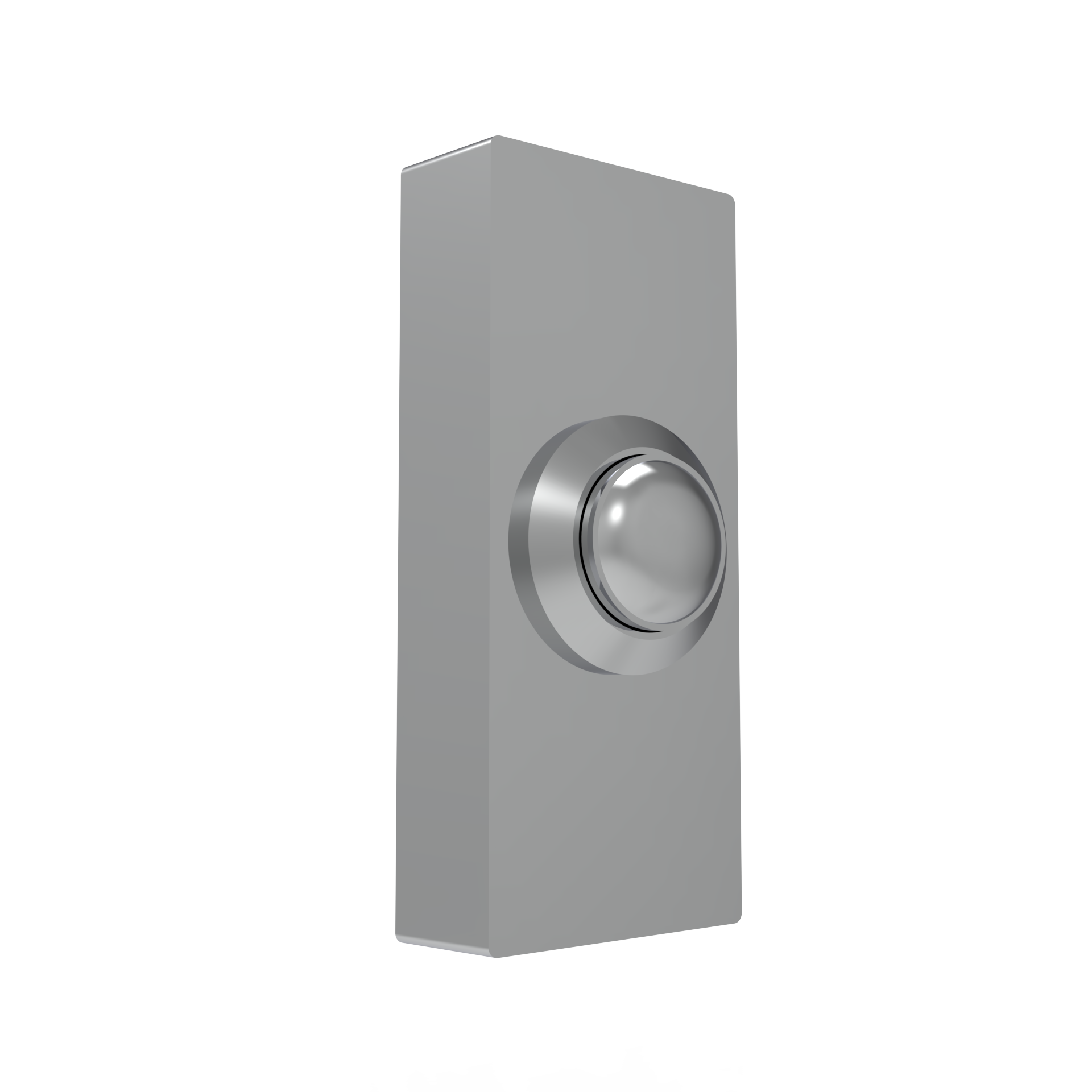

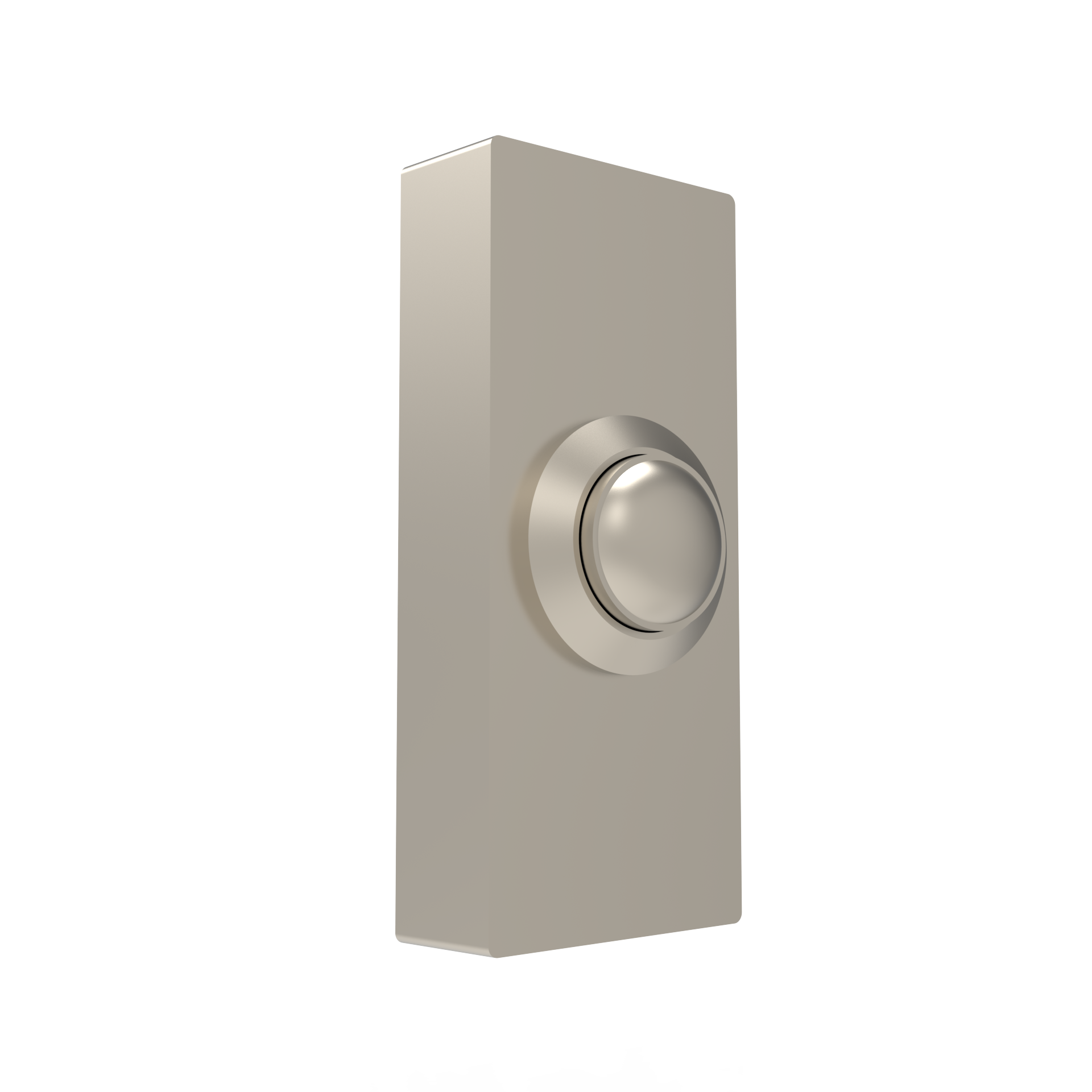

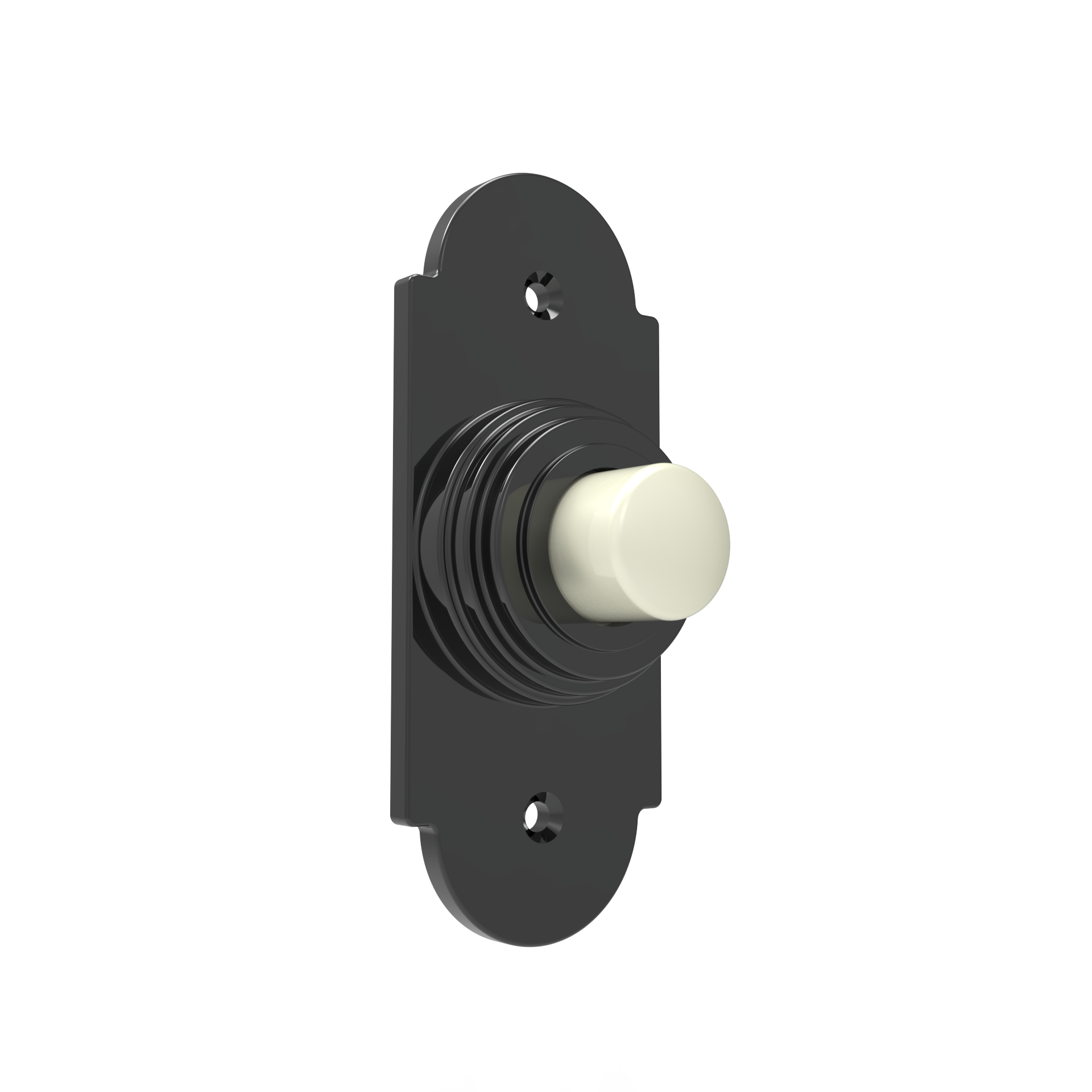

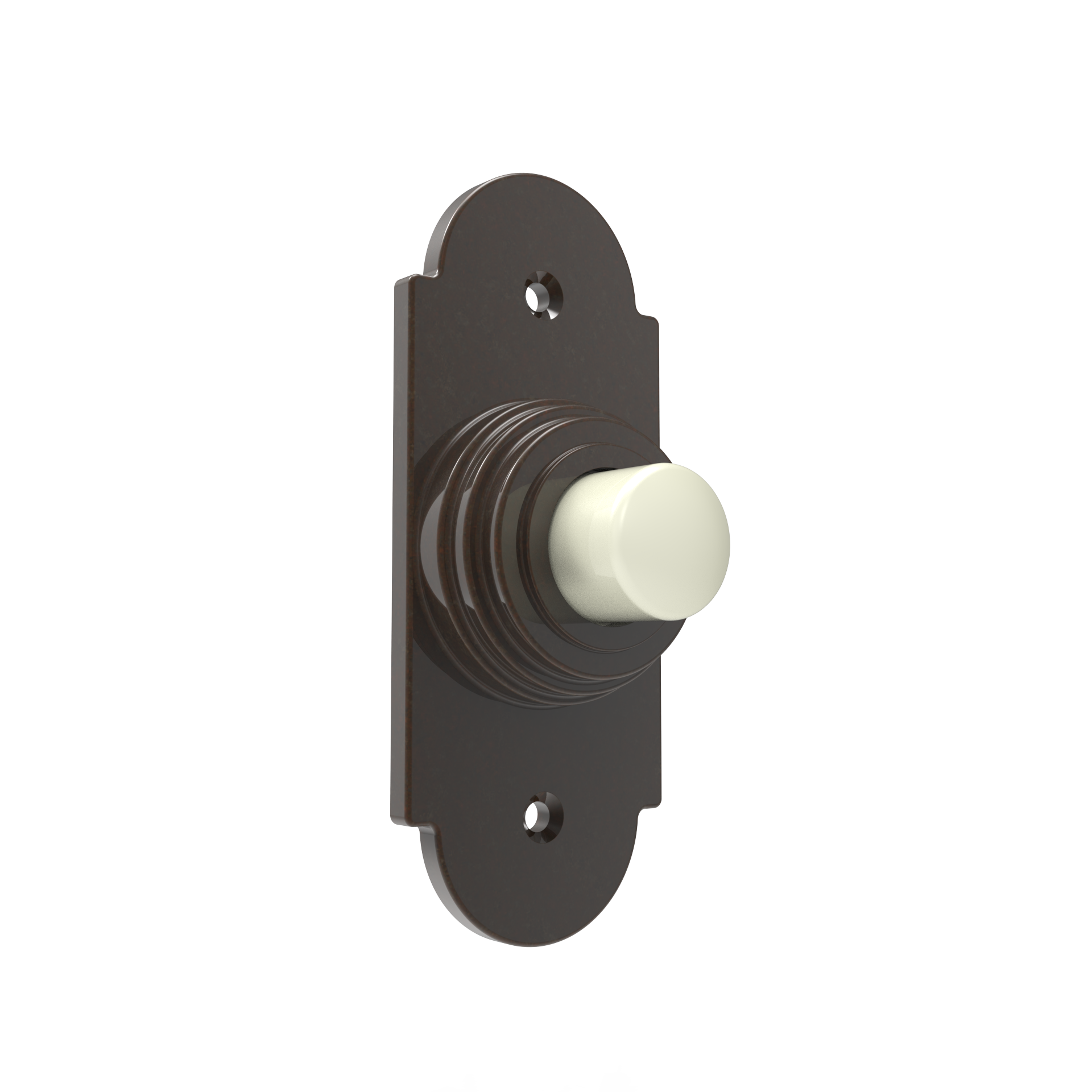

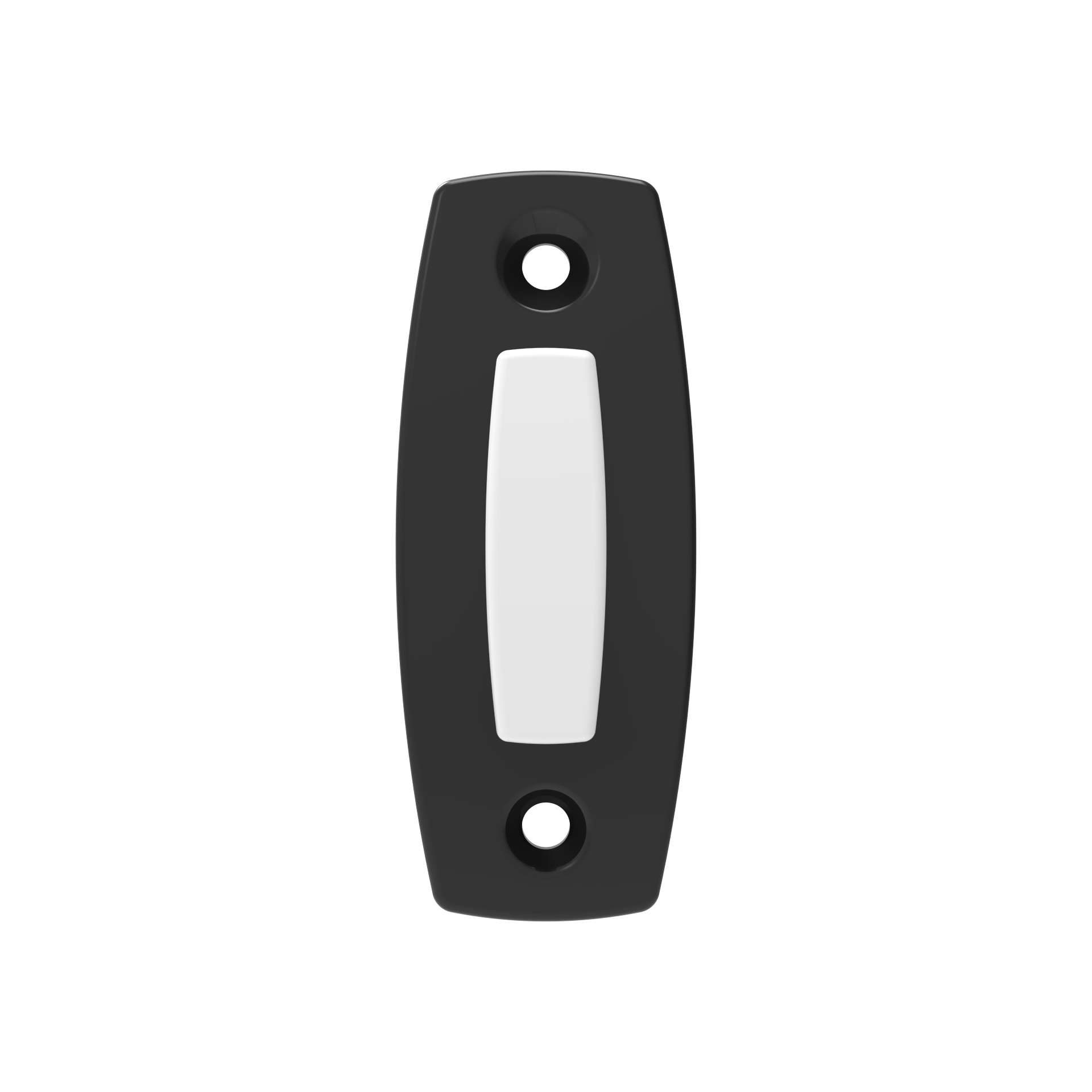

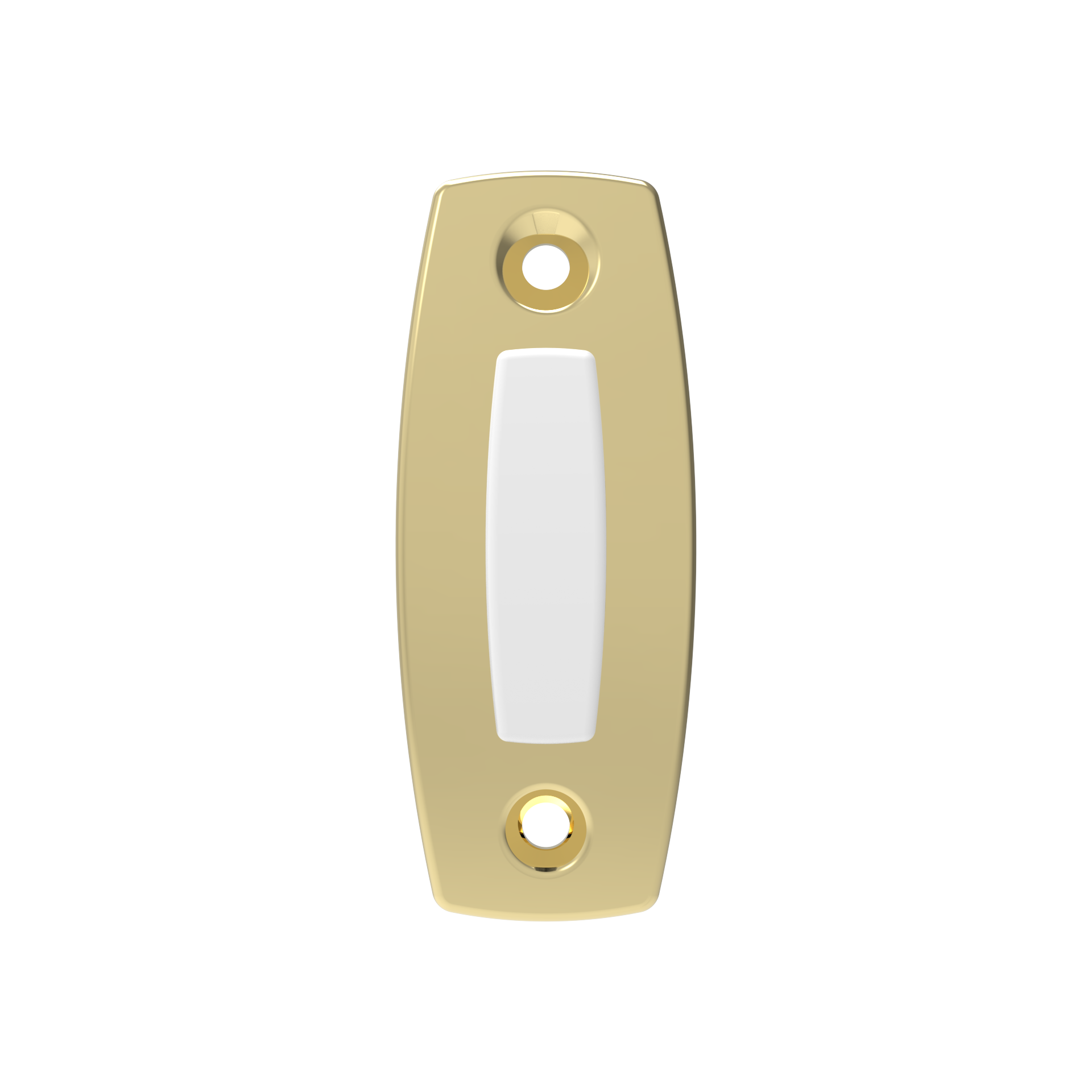

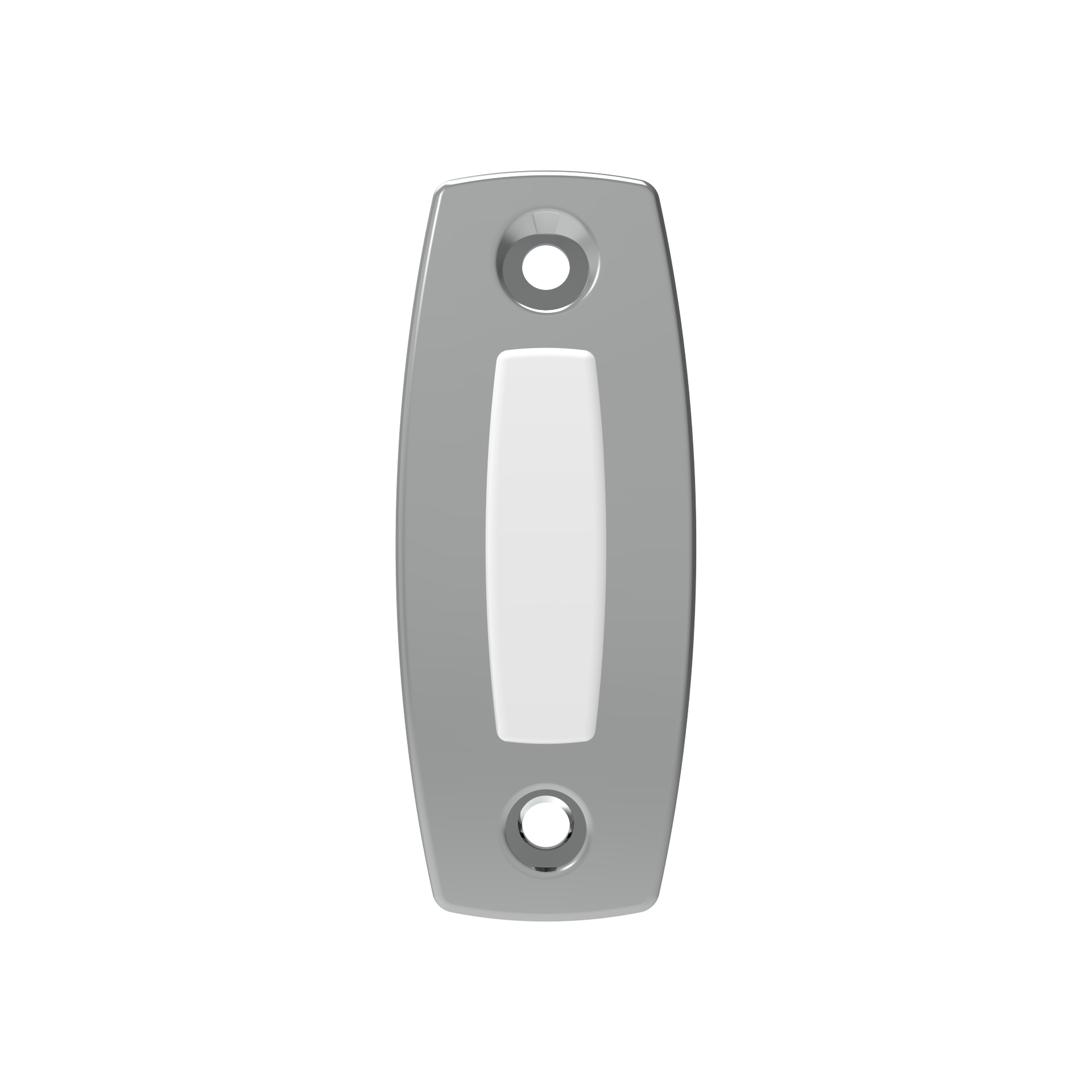

KeyShot Renders.

Windup doorbell had an existing website and existing photo product images. However, their main concern was the consistency of there imagery. Photography (like laser scanning) always adds a challenge when working with metallic objects.

To improve consistency, we chose to render each product with KeyShot. This allowed for consistent camera placement, lighting and material finish.

3D AR Models

The client also requested 3D AR models of each product to improve customer interaction on their site. The main reason this was so successful was thanks to our lightweight parametric model, yes, you can use scanned STL data to achieve the same effect, but this data would have much larger and created longer website load times. The .GLB files we created from our parametric models were on average 5MB, which allowed quick and responsive load times.

The main challenge in creating these AR models was writing the code that allows the model viewer window to toggle between different variants. Previously when we have created AR models for other customers, we have only worked with a single 3D model, which was great for learning a new skill.

Final Website.

The final website along with all our models, renders and 3D models can viewed at www.windupdoorbells.com