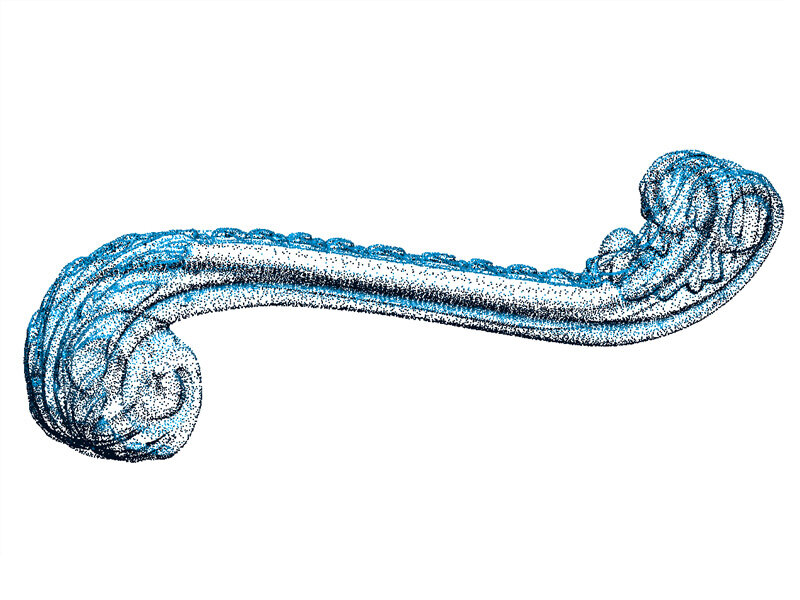

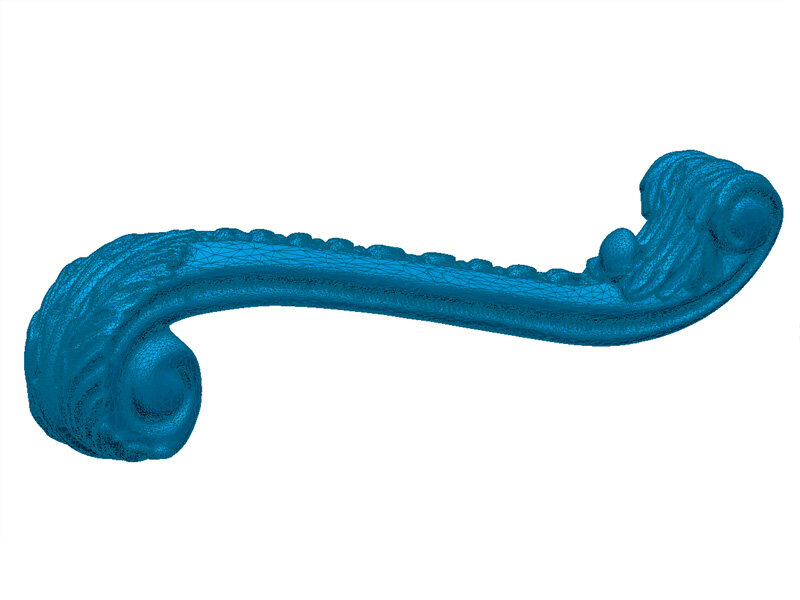

Case Studies.

Brass Handles

Scan for 3D print restoration.

Another laser scanning company contacted us to help them with an important restoration project where they were having difficulty capturing the intricate detailing on the historic handle.

Due to the complexity of the shape and its freeform surface, to ever build this model accurately from scratch would be near impossible, however with the surfacing tools in Geomagic Design X this was not an issue.